Absolutely — heres a more technical version of the product description for cartridge filters specifically tailored to professionals in the water, wastewater, and desalination sectors:

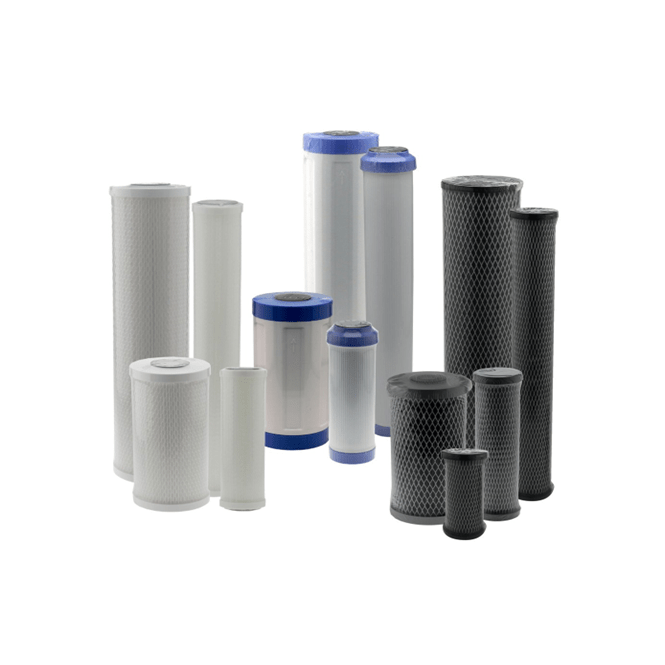

Cartridge Filters for Water, Wastewater, and Desalination Applications

Engineered Filtration for Critical Process Reliability

Our industrial-grade cartridge filters are designed for high-efficiency particulate removal in water and wastewater treatment, as well as pre-treatment stages in desalination systems. These filters offer precise and consistent micron ratings to safeguard sensitive downstream equipment and optimize system performance under variable flow and loading conditions.

Technical Specifications:

-

Micron Ratings: 0.2 µm to 100 µm (absolute and nominal options)

-

Media Types: Melt-blown polypropylene, pleated polypropylene, PES membrane, activated carbon, glass fiber

-

Core/Coreless Construction: With or without polypropylene or stainless steel cores for pressure resilience

-

End Configurations: DOE, SOE (222/226 O-rings with fin or flat caps), custom adapters available

-

Length Options: Standard lengths from 10” to 40”; custom lengths on request

-

Operating Temperature: Up to 80°C (PP), 120°C (glass fiber); higher on request

-

Differential Pressure Rating: Up to 2.5 bar (36 psi) change-out recommended

-

pH Compatibility: 1–13 depending on media

Performance Features:

-

High Surface Area Design: Maximizes dirt-holding capacity, minimizes replacement frequency

-

Low Initial ΔP: Ensures minimal pressure drop across cartridge at rated flow

-

Consistent Pore Structure: Ensures predictable filtration behavior and contaminant retention

-

Thermally Bonded Construction (Melt-blown models): Eliminates media migration and bypass

-

Pleated Configurations Available: For extended service life and high flow applications

Applications by Industry:

-

Water Treatment: Pre-filtration for multimedia, UF/RO systems; post-treatment polishing

-

Wastewater Treatment: TSS reduction before secondary/tertiary processes; pre-disinfection filtration

-

Desalination Plants: Pretreatment before SWRO/RO membranes; filtration of well or surface feedwater

-

Industrial Water Systems: Boiler feed pre-filtration, cooling tower sidestream filtration, CIP rinse water

Advantages:

-

Enhances membrane and UV system longevity by capturing colloidal and particulate fouling agents

-

Reduces fouling and scaling risks in high-pressure desalination applications

-

Maintains stable system hydraulics and flow rates even under variable influent conditions

-

Compatible with automated filter housings and skid-mounted systems

Available

Available