Ta

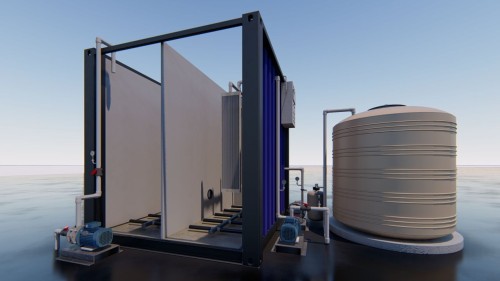

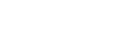

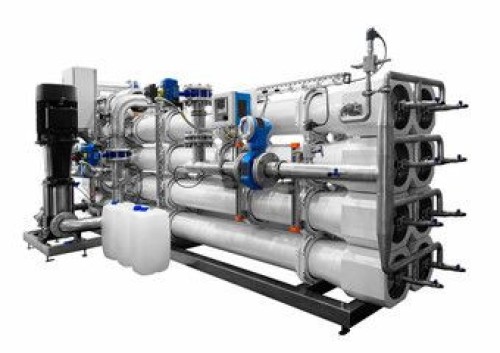

SewageSavvy Pod: Elite Containerized Sewage Treatment Plant with Cutting-Edge MBR TechnologyUnmatched Performance and Versatility for Global Excellence Introducing the SewageSavvy Pod, the pinnacle of containerized sewage treatment technology by DASK JALMART PVT. LTD.. Designed for maximum efficiency and adaptability, the SewageSavvy Pod integrates advanced Membrane Bioreactor (MBR) technology with innovative ozone disinfection processes. Engineered to meet the most stringent global standards and environmental regulations, this high-performance modular system is ideal for a wide range of applications across the globe. Advanced Technological Integration Optimized Containerized Design Dimensions: Available in both standard 20 ft and 40 ft ISO containers, the SewageSavvy Pod ensures efficient logistics and quick deployment. Its compact design allows for easy integration into diverse infrastructures with minimal setup time, providing flexibility for various operational environments. Durability: Constructed using high-strength, marine-grade stainless steel (316L) and advanced composite materials, the system offers exceptional resistance to corrosion, wear, and environmental stresses, guaranteeing robust and long-term performance. Sophisticated Treatment Technology Primary Treatment: High-Efficiency Screening: Equipped with mechanical screens featuring automatic cleaning systems, the SewageSavvy Pod efficiently removes large solids and debris, optimizing the performance of subsequent treatment stages. Grit Removal Systems: Utilizes advanced vortex or centrifugal grit removal technology to effectively separate inorganic materials, protecting downstream equipment from damage and fouling. Secondary Treatment with MBR Technology: Membrane Bioreactor (MBR): Combines biological treatment with membrane filtration to provide superior organic matter reduction and precise solid-liquid separation. This ensures exceptional effluent quality and offers operational flexibility. Activated Sludge Process: Incorporates fine bubble aeration, high-efficiency diffusers, and a variable-speed blower system, optimizing microbial digestion of organic contaminants, enhancing oxygen transfer, and reducing energy consumption. MBR Membranes: Features ultra-filtration membranes with a pore size of 0.03 microns, effectively removing suspended solids, bacteria, and other contaminants. The MBR technology is available in both submerged and external configurations to meet operational needs. Automated Membrane Maintenance: Equipped with sophisticated backwashing and Chemical Cleaning-In-Place (CIP) systems, the SewageSavvy Pod ensures optimal membrane performance and extends service life, reducing maintenance downtime. Tertiary Treatment with Ozone Disinfection: Ozone Generation: Utilizes high-efficiency corona discharge technology for on-site ozone production, delivering powerful disinfection and oxidation to break down residual pollutants and pathogens. Ozone Contact Chamber: Designed for optimal ozone mixing with treated effluent, ensuring thorough pathogen inactivation and degradation of trace contaminants. Ozone Destruction: Equipped with ozone destruction units that use catalytic or thermal methods to safely decompose excess ozone before discharge, ensuring compliance with strict environmental standards and protecting receiving water bodies. Exceptional Energy Efficiency Aeration Control: Advanced aeration systems with variable frequency drives (VFDs) provide precise air supply management, reducing energy consumption while maintaining high treatment efficiency. Energy Recovery: Incorporates waste heat recovery technologies, capturing and reusing energy from various processes to enhance system efficiency and lower operating costs. Membrane Cleaning: Automated CIP systems with advanced chemical dosing protocols ensure effective membrane maintenance with minimal chemical usage and reduced operational interruptions. State-of-the-Art Control and Automation High-Performance PLC System: Equipped with a sophisticated Programmable Logic Controller (PLC) and an intuitive Human-Machine Interface (HMI), the system allows real-time process control, performance monitoring, and data analysis, all with fail-safe protocols and redundancy for added reliability. SCADA System Integration: Seamlessly integrates with advanced SCADA systems for secure remote monitoring and control. This allows for real-time data access, diagnostics, and operational management via internet or VPN from any location worldwide. Comprehensive Instrumentation: Includes a full array of sensors for precise process control, such as flow meters, level sensors, pressure transmitters, dissolved oxygen meters, ozone concentration monitors, and membrane flux sensors. Operational Excellence Automated Sludge Management: Features advanced systems for sludge thickening, dewatering, and disposal, minimizing manual intervention and optimizing operational efficiency. Self-Cleaning Mechanisms: Integrated self-cleaning and backwashing systems for filters ensure continuous, high-performance operation with minimal maintenance requirements. Data Logging and Reporting: Provides detailed data logging capabilities and customizable reporting options for performance tracking, regulatory compliance, and optimization of operations. Global Compliance and Certification International Standards: Fully compliant with global standards such as ISO 9001 for quality management, as well as regional and international environmental regulations for treated wastewater discharge. Rigorous Certification: Undergoes comprehensive factory acceptance testing (FAT) and performance validation to ensure it meets the highest industry standards for quality and operational performance. Tailored Customization and Seamless Integration Bespoke Solutions: The SewageSavvy Pod is fully customizable to meet specific client requirements, including adjustments for influent characteristics, treatment capacity, and environmental conditions. Designed for seamless integration into existing infrastructure, it offers flexibility for diverse operational needs. Comprehensive System Integration: Compatible with additional components such as advanced odor control systems, post-treatment polishing units, and telemetry solutions, providing a holistic approach to wastewater management. Applications for Diverse Global Needs The SewageSavvy Pod excels across a broad spectrum of applications, including: Remote and Rural Areas: Offers reliable sewage treatment for regions with limited infrastructure, improving access to clean water and sanitation. Construction Sites: Effectively manages sewage from temporary facilities, ensuring compliance with local and international environmental regulations. Military and Defense: Provides portable, resilient sewage treatment solutions for military operations in remote or challenging environments, with rapid deployment capabilities. Disaster Response: Perfect for emergency and humanitarian aid, delivering essential wastewater treatment during natural disasters and crisis situations. Industrial and Municipal: Provides high-performance treatment for industrial processes and municipal applications, ensuring high-quality effluent and compliance with global discharge regulations.

.png)